|

|

RECOMMENDATION |

FEATURES |

RANGE |

OPERATING PARAMETERS |

|

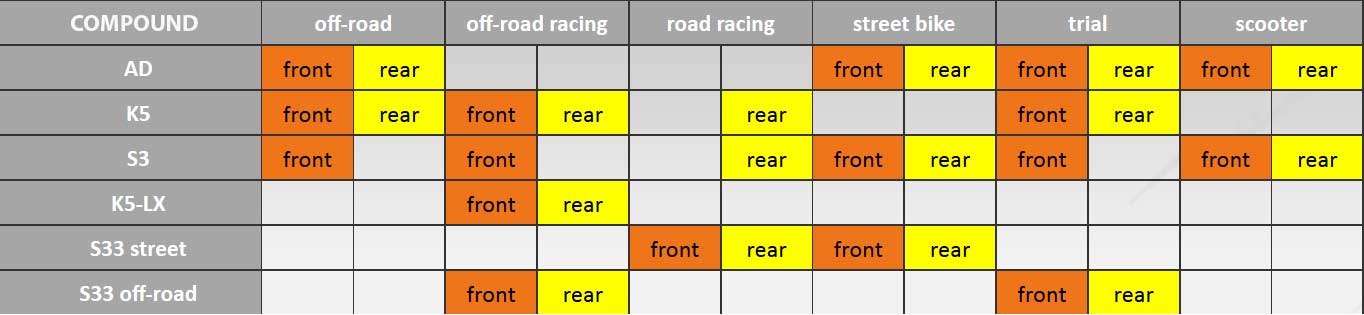

AD |

-

Recommended for riders that do not ride really hard, but do want the good stopping power of a sintered brake pad when needed.

-

Optimal for street bikes, dual sport, touring trial & cruisers.

-

Designed for very low abrasive interaction with the rotor and offers quieter braking due to the ceramic composite material.

-

This compound makes for a perfect OE replacement due to its versatility.

|

-

high static friction coefficient

-

good abrasive resistance

-

low abrasive interaction with the brake rotor material

-

3x longer operational life compared to organic and Kevlar composite materials

|

-

specifically designed for common street riding

-

can be used on off-road bikes *front brake* for riders that don't ride hard

|

-

Specific pressure: P<5.0 Mpa

-

Sliding speed: V<40 m.s-1

-

Contant Max Temp: 450C

-

Short Term Max Temp: 700C

-

Counter-surfaces: steel discs

|

|

K5 |

-

Recommended for riders who demand great off-road stopping power and brake pad durability when riding on tough off-road terrain.

-

Optimal for off-road dirt bikes and ATV's.

-

Designed for low abrasive interaction with the rotor, long life and self-cleaning capabilities necessary for off-road riding conditions.

|

-

high static friction coefficient

-

good abrasive resistance

-

thermal stability up to 500C and even up to 750C over a short term

-

self-cleaning capability

-

low abrasive interaction with the brake rotor material

-

3x longer operation life compared to organic and Kevlar materials

|

-

developed for off-road applications because it features long life on heavy duty terrain

-

can be used on both front & rear brakes

-

for hot & dry weather use only on rear brake

|

-

Specific pressure: P<2.0 Mpa

-

Sliding velocity: V<20 m.s-1

-

Constant Max Temp: 500c

-

Short Term Max Temp: 750C

-

Counter-surfaces: steel discs

|

|

S3 |

-

Recommended on applications for larger engines or for people who ride harder than average and want the great stopping power of a sintered pad.

-

Optimal for street bikes, dual sport, touring & cruisers.

-

Designed for low abrasive interaction with the rotor and quieter braking because of the ceramic composite material.

-

High HH friction rating; performs better at higher temperatures than the AD compound.

|

-

very high static friction coefficient

-

minimal difference between wet & dry braking performance

-

good abrasive resistance

-

thermal stability up to 450C and even up to 800C over a short term

-

low abrasive interaction with the brake rotor material

-

3x longer operation life compared to organic and Kevlar materials

|

-

developed for larger street bikes

-

can be used on both front & rear brakes

-

works well in both dry & wet conditions

-

use on the front brakes for off-road bikes & ATV's

|

-

Specific pressure: P<3.0 Mpa

-

Sliding speed: V<45 m.s-1

-

Constant Max Temp: 450C

-

Short Term Temp: 800C

-

Counter-surfaces: steel discs

|

|

K5-LX |

-

Recommended for off-road riders who are looking for a competitive edge and great stopping power.

-

Optimal for pro level off-road racers who demand great braking performance & pad life.

-

Designed for low abrasive interaction with the rotor, long life and self-cleaning capabilities for off-road riding conditions.

-

K5-LX rear pads feature a stainless steel heat shield for thermal isolation.

-

Friction materials contain metal-ceramic with a very sophisticated bronze-graphite and a full-metal formulation with fine friction particles to achieve optimal friction properties.

|

-

high static friction coefficient

-

good abrasive resistance

-

thermal stability up to 500C and even up to 750C over a short term

-

low abrasive interaction with the brake rotor material

-

3x longer operation life compared to organic and Kevlar materials

|

-

developed for high level & demanding off-road riders of dirt bikes & ATV's

-

can be used on both front & rear brakes

-

when using on front brakes there could be higher abrasion on the pads

-

K5-LX is used by riders in motocross & enduro championships

|

-

Specific pressure: P<2.0 Mpa

-

Sliding speed: V<20 m.s-1

-

Constant Max Temp: 500C

-

Short Term Temp: 750C

-

Counter-surfaces: steel discs

|

|

S33 |

-

Optimal for ambitious first-class pro level off-road riders who demand the ultimate edge on their racing with excellent stopping power and exceptional longevity.

-

Designed for low abrasie interaction with the rotor while providing high braking power, long life and self-cleaning capabilities necessary for off-road riding conditions.

-

S33 rear pads feature a stainless steel heat shield for thermol isolation.

-

Compound contains all-metal friction materials designed to achieve the greatest friction properties possible under heavy conditions.

|

-

High static friction coefficient across the whole scope of operating condition

-

Low aggressiveness in contact with the brake disc and sufficient resistance to abrasion

-

Self cleaning capability

-

Thermal stability up to 600°C, and up to 850°C over a short term

-

Long service life

-

Environment-friendly

-

Manufactured by means of a progressive method of powder metallurgy

-

Stainless steel heat shield for thermal isolation on the rear pads

-

The metal-ceramic material can undergo friction in both wet and dry conditions

|

-

ideal choice for world off-road championships

-

also used on high performance street bikes

-

excellent brake power and service life

-

while it can be used on both front a rear brakes, it's mainly for the rear brake

|

-

Specific pressure: p< 5 Mpa

-

Sliding speed: v< 20 m/s

-

Max. stable temperature: 600°C

-

Short-term temperature: 850°C

-

Counter-surfaces: steel disks

|

View Order / Checkout

View Order / Checkout Continue Shopping

Continue Shopping