GOLDfren sintered brake pad compounds contain a mixture of non-aggressive friction materials, metals and fibers as well as metal-ceramic and ceramic-carbon. GOLDfren brake pads provide excellent stopping power with minimal rotor wear and tear.

As long as the brake pad friction materials are non-aggressive, they will not cause any more than normal wear on the rotors. Friction with the rotor is required for your motorcycle to stop so normal levels of wear and tear should be expected.

It's important to use sintered brake pads because of their superior brake power and durability.

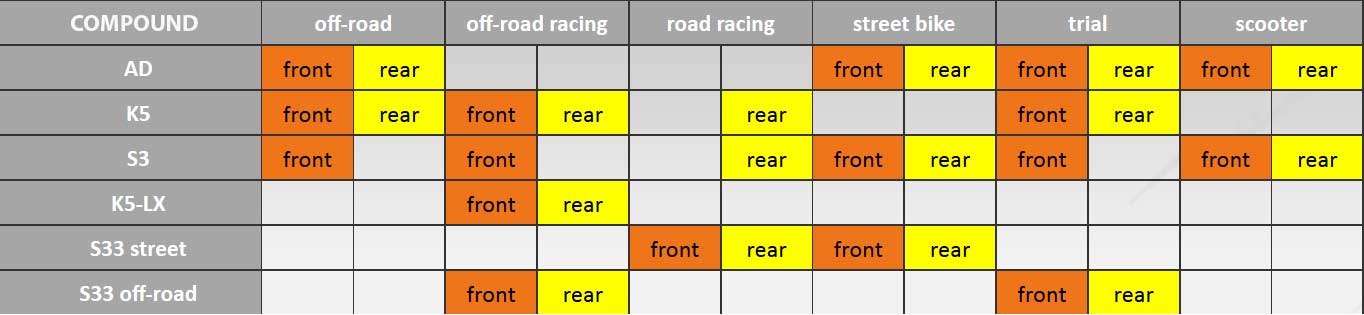

You can use any of the following GOLDfren sintered compounds for motocross: K5, K5-LX or S33 off-road. GOLDfren's professional motocross and supercross riders currently use S33 off-road compound.

For road racing GOLDfren recommends using any of the GP compounds on the front brakes and S33 street or possibly S3 on the rear brake.

The S3 series brake pad is suitable for common street riding on street bikes and cruisers with rather larger engines. It is recommended for riders who ride harder than average and want great stopping power.

On the other hand, the S33 comes in two types offroad and street. The S33 (offroad) series brake pad is optimal for ambitious first-class pro level off-road riders who demand the ultimate edge on their racing with absolute great stopping power and exceptional brake pad longevity.

The S33 (street) series is also ideal for street bikes, touring bikes, or even cruisers; recommended for riders who demand sintered brake pads with best performance and durability.

Sintered pads are made by fusing together metallic particles under high temperatures and pressure using a pressed powdered-metal technology to enhance friction properties and pad life. The end result is longer life and stronger braking.

There are several terms used for this procedure: bed-in, run-in, break-in, conditioning or burnishing.

Making sure that your newly installed brake pads are properly bedded-in is the prerequisite for their long lifetime and for a reliable braking effect. The goal of this process is to achieve the most possible active brake pad surface contact with the brake rotor disc.

First of all, please beware that braking performance on newly installed brake pads may be less than what you are expecting therefore, please allow some extra braking space during the bed-in period.

To bed-in your brake pads, brake several times at lower speeds then very carefully brake a few times at higher speeds then allow the brake pad lining to cool down while driving. The bed-in process usually takes between 100 to 300 miles. After this bed-in procedure you will start noticing increased braking power at which point you may use your brakes normally.

The HH refers to the friction coefficient of the brake pad braking material, it means that the coefficient of friction is over 0.55 when both cold and hot.

HH rated brake pads offer more stopping power for a given force applied on the brake lever than other friction ratings such as GG and FF. But that doesn't make HH brake pads better, it's more a matter of riding style and preference. GOLDfren brake pad compounds with HH rating are S3, S33 and GP.

View Order / Checkout

View Order / Checkout Continue Shopping

Continue Shopping